Sandeep Mistry

Gokul Suryamurthy

(Sep 2018 - Dec 2018)

Design Problem Statement:

Existing Gimbal system in market were bulky and huge in size to bear 1 - 4 Kg of payload which led to novel refinement of Gimbal design being compact,reliable, robust and required strength to bear LIDAR and camera payload weighing up to 4 Kg.

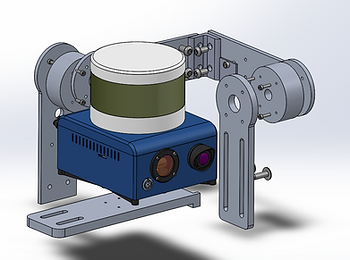

PROTOTYPE 1 FOR UAV

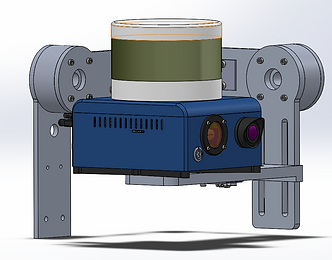

PROTOTYPE 2 FOR UGV

Individual contribution:

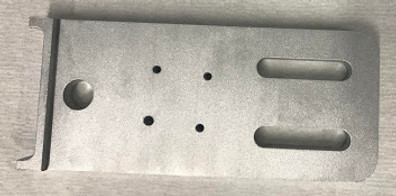

Prototype 1:

-

Executed sheet metal design of pitch shoulder with 45 degree bends at two point.

-

Created flat pattern out of Al 6061 and implemented brake press for bending Al sheet metal.

-

Tested the prototype by manual balancing 1.5 Kg of payload and aligning it with the CG of system.

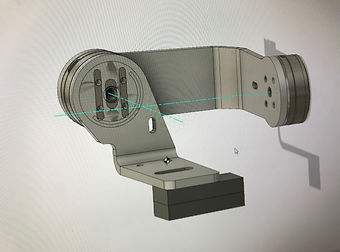

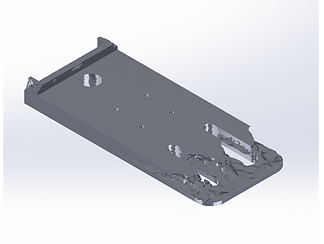

Prototype 2:

-

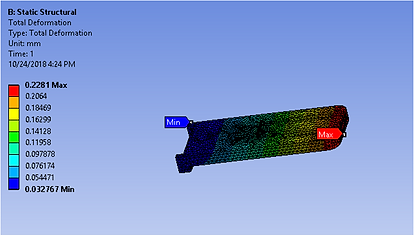

Designed pitch platform for 3 Kg of payload by appropriate material selection using Al 6061 and redesigned it through topology optimization.

I fabricated both the prototypes through Brake press, CNC and Knee mill.

3D model: Prototype 1 & 2

Fabrication: Prototype 1 & 2:

Balancing & testing Prototype 1:

FEA Analysis & topology Optimization:

Future work:

-

Implementing Flex and Rover Hammer Impact test to detect structural rigidity with FEA results and modal frequency to avoid structural failure at resonance respectively.

-

Integrating the optimised Gimbal assembly in UAV and UGV and testing the data accuracy captured by LIDAR and multiple cameras in 1m x 1m span range, vertical & 100 % slope inclination environments to succeed in Physical testing category of DARPA's Subterranean challenge.